Detailed Design

Note: As mentioned on the Interface Design page, many of the examples will be scoped to a particular part of the overall system under development. Detailed design artifacts are going to contain a large amount of details which, if included in full, would obscure the point of this page.

The detailed design should represent the system design in a variety of views where each view uses a different modeling technique. By using a variety of views, different parts of the system can be made clearer by different views. Some views are better at elaborating a systems states whereas other views are better at showing how data flows within the system. Other views are better at showing how different system entities relate to each through class taxonomies for systems that are designed using an object-oriented approach.

A template for detailed design would not be of much use since each detailed design is likely to be unique and quite different from other designs. What is helpful in regards to guidance on detailed design are examples. This page provides some detailed design content for the example microwave oven system that is referenced periodically by this website.

The major sections of this web page are the following:

- Structural Chart

- Control-Flow Model

- Class Diagram

- Collaboration Diagram

- Sequence Diagram

- Activity Diagram

- Pseudocode

- V-Model Diagram

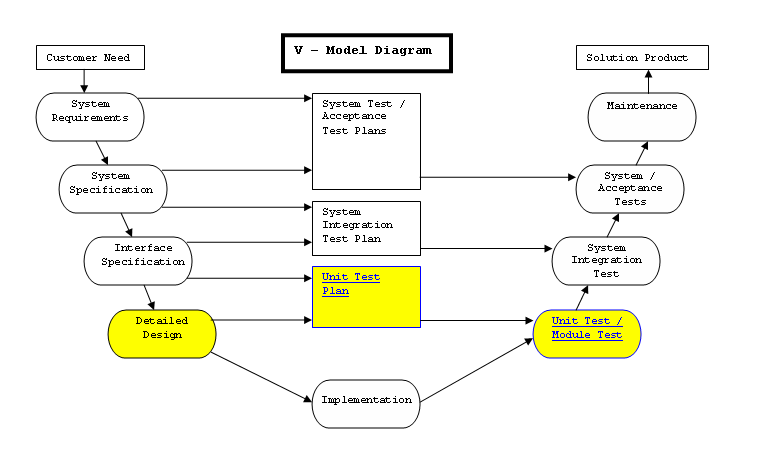

Structural Chart

The intent of a structural chart is to specify the components (boxes) of the system under development along with the interactions (arcs) that take place between those components.The structural chart diagram below is an overall system diagram for the microwave oven example and is therefore has a very high information density.

Data Dictionary:

|

Entity

Name |

Type |

Description |

|

Auto Cook Presets |

FUNCTION |

Looks up proper

power level and

cooking time settings for a given auto cook preset food item |

|

Auto Defrost |

FUNCTION |

Determines correct

power level

and cooking time values based on type of meat and weight of meat being

defrosted |

|

Beeper |

FUNCTION |

Sounds beeper tone

for

specified length of time |

|

Beeper duration

time |

INTEGER |

The number of

seconds that the

beeper is to sound a tone. |

|

Clock |

FUNCTION |

Begins measuring

time from an

initial time of day input |

|

Clock start time |

TIME_H_M |

Operator entered

time value

used to initialize the clock |

|

Cooking Control |

FUNCTION |

Sends signals to

set oven

control function to set proper power level then turn oven on for the

length of time specified in the input to this function |

|

Current time of day |

TIME_H_M |

Current time of

day to be

displayed |

|

Current timer value |

TIME_M_S |

Current timer

value to be

displayed |

|

Display Power |

FUNCTION |

Sends power level

setting to

LCD screen to be displayed |

|

Display Time |

FUNCTION |

Sends time setting

to LCD

screen to be displayed |

|

Door opened

interrupt |

ENUMERATION |

Door closed = 0,

Door open = 1 |

|

Door switch signal |

DOOR_SWITCH |

Signal from door

sensor to

indicate whether the microwave door is opened or closed |

|

Echo digits 0-9 |

ECHO_DIGITS |

Echo digits 0-9 to

LCD screen

as operator presses these keys |

|

Feedback tones |

FEEDBACK_TONES |

Sound tones after

each key is

entered |

|

HW Beeper on off

signal |

HW_BEEPER_CNTL |

Discrete signal to

beeper

hardware to turn beeper on and off |

|

HW Oven on off

signal |

HW_OVEN_CNTL |

Discrete signal to

microwave

generator hardware to turn oven on and off |

|

HW Power level |

HW_PWR_LEVEL |

Signal to set

microwave

generator hardware to correct value |

|

Initial timer value |

TIME_M_S |

The operator

entered time value

used to initialize the timer |

|

Keypad input

signals |

KEYPAD_INPUTS |

Input signals from

keypad

hardware |

|

LCD Power level |

LCD_PWR_LEVEL |

Power level

formatted for

display on LCD screen. |

|

LCD Time |

LCD_TIME |

Time value (XX:XX)

sent to LCD

screen (can be either in hours, minutes or in minutes, seconds

depending on which microwave function is active) |

|

Meat type |

ENUMERATION |

Type of meat (Beef

= 1, Poultry

= 2, Fish = 3) |

|

Monitor and

Process Inputs |

FUNCTION |

Receives and

decodes inputs

from keypad and door sensor then calls appropriate sub-functions |

|

Operator prompts |

OPER_PROMPT |

Operator prompts

sent to the

LCD screen to request operator inputs |

|

Oven on/off signal |

ENUMERATION |

Off = 0, On = 1 |

|

Oven Control |

FUNCTION |

Sends power level

settings to

microwave generator hardware then turns microwave generator hardware on

and off as inputs indicate |

|

Power level |

INTEGER |

Power level

selected by

operator (1 – 10) |

|

Preset selected |

ENUMERATION |

Preset key

selected by operator

(Popcorn = 0, Potato = 1, Beverage = 2, Pizza = 3, Frozen

Entrée = 4, Fresh Veg. = 5) |

|

Remaining cooking

time |

TIME_M_S |

Length of time

before cooking

completes |

|

Start |

ENUMERATION |

Indicates that the

Start button

has been pushed (Start active = 1, Start inactive = 0) |

|

Stop/Clear

interrupt |

ENUMERATION |

Stop/Clear button

indication

signal (Stop/Clear active = 1, Stop/Clear inactive = 0) |

|

Timer |

FUNCTION |

Receives an

initial timer value

then counts down the time to 00:00 and sends a signal to the beeper

function to sound a tone. |

|

Weight of meat |

FLOAT |

Weight of meat for

defrosting

in ounces |

Control-Flow Model

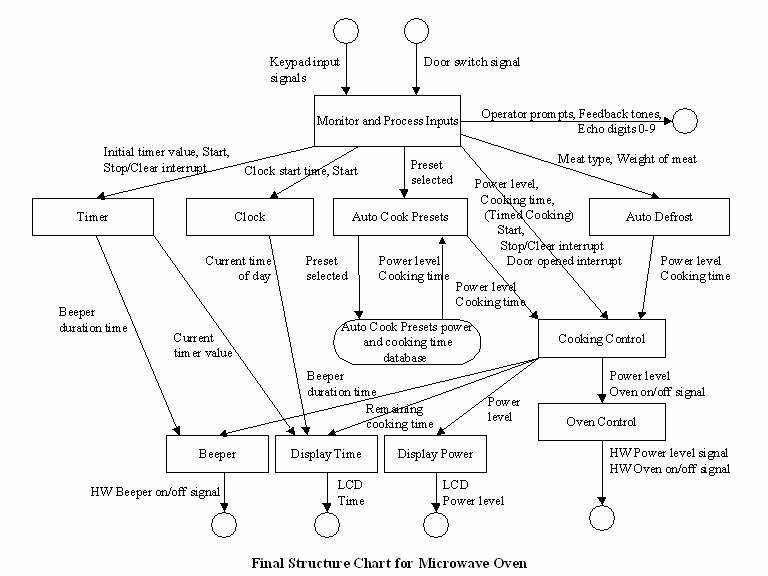

A Control-Flow Diagram (CFD) models the flow of execution through data objects. This is a venerable approach to specifying the flow design of a system with a great amount of precision. UML offers a collection of diagrams to convey the same type of system information. These diagrams are activity diagrams, collaboration (object-interaction) diagrams, and sequence diagrams.Each rhomboid represents a software object and each directed arc represents a single flow of control ordinally segmented according to the call sequences. The following control flow diagram models the control flow of the auto-defrost operation of the microwave oven example.

Data Dictionary:

|

Term |

Description |

Type |

Requirements

Trace |

|

Auto-Defrost

Key Object |

Process

scope of Auto-Defrost Key control flow. |

Process

Entity |

|

|

Controller

Object |

Process

scope of Controller control flow with respect to Auto-Defrost Key

interaction. |

Process

Entity |

|

|

Display

Prompt |

Process

within Controller Object processing scope that displays prompts for

requesters. |

Sub-Process

Entity |

|

|

Handle

Auto-Defrost Key Event |

Process

within Auto-Defrost Key Object processing scope that handles events as

they occur. |

Sub-Process

Entity |

|

|

Keypad |

Keypad

input device. |

Hardware

Component |

|

|

Process

Meat Type |

Process

within Auto-Defrost Key Object processing scope that processes data for

the meat type selected. |

Sub-Process

Entity |

|

|

Process

Meat Weight |

Process

within Auto-Defrost Key Object processing scope that processes data for

the meat weight selected. |

Sub-Process

Entity |

|

|

Prompt

for Meat Type |

Process

within Auto-Defrost Key Object processing scope that requests display

of meat type prompt. |

Sub-Process

Entity |

|

|

Prompt

for Meat Weight |

Process

within Auto-Defrost Key Object processing scope that requests display

of meat type prompt. |

Sub-Process

Entity |

|

|

Start

Defrost Operation |

Process

within Controller Object processing scope that communicates with the

generator to start cooking. |

Sub-Process

Entity |

|

|

Wait

for Start Button Press |

Process

within Auto-Defrost Key Object processing scope that waits for user

acknowledgement of selection via the start button event. |

Sub-Process

Entity |

Class Diagram

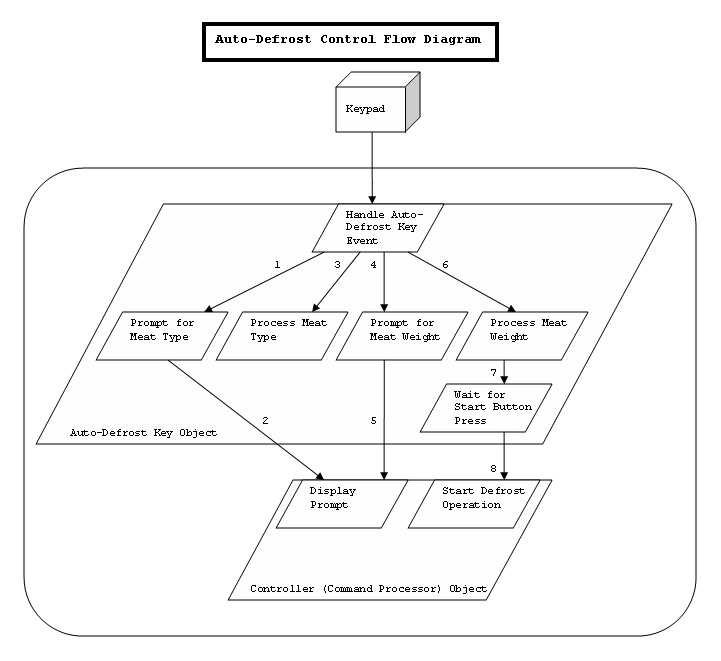

A class diagram is a superset of an inheritance model in that it models the class taxonomy; however, it also models relationships between the various class entities like a semantic model.A class diagram is a type of UML (Unified Modeling Language) diagram. A class diagram describes the various entities that will be used to construct the functioning system. Describing object (an object is an instantiated class much like a process is an instantiated program) attributes and operations allows the developer to begin to logically apportion data and functions in a fashion that is natural to human beings. Participating objects are defined via their classes (or templates). Their capabilities, their roles, and their associations / relationships are specified. By specifying the classes from which objects are created, a developer is essentially adding parts to a kit from which a fully functional system will be produced. This type of model is iterative. It may start with classes that only have names. As the developer's understanding of the problem improves, the developer can begin to add the necessary attributes and operations that the classes will need. In this way, the solution system is systematically developed increment by increment.

The following class diagram models the system inputs for the microwave oven example and is the same diagram displayed on the Interface Design page.

Data Dictionary:

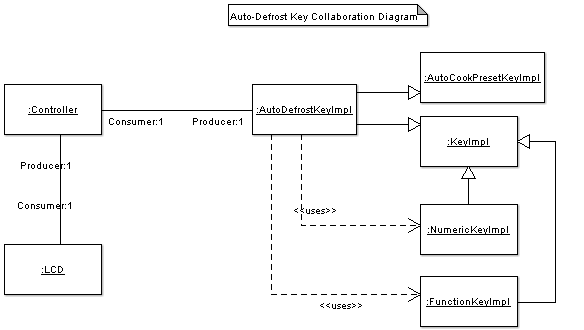

Please refer to the data dictionary for this diagram on the Interface Design page.Collaboration Diagram

A collaboration defines a collaborative effort between cooperating objects. Again, an object is an instance of a class. The collaboration diagram models the interactions that take place between the colloborating objects to affect a desired end result.The following collaboration diagram models the interaction between objects that cooperate to provide the auto-defrost functionality for the microwave oven example.

Data Dictionary:

|

Term |

Description |

Type |

Requirements

Trace |

|

AutoCookPresetKeyImpl |

Parent

class object to AutoDefrostKeyImpl class object that contains and

processes cooking duration and power level data. |

Object |

|

|

AutoDefrostKeyImpl |

Class

object that contains and processes type of meat and meat weight data. |

Object |

|

|

Consumer |

Role

stereotype of object association that shows the object is a consumer of

data via the association arc. |

Association

Role |

|

|

Controller |

Class

object that manages controller data and system state and provides

services to other system objects. |

Object |

|

|

FunctionKeyImpl |

Class

object that is used (indirectly) by the AutoDefrostKeyImpl class

object. FunctionKeyImpl class object provides Start button

functionality. |

Object |

|

|

KeyImpl |

Parent

class object to AutoDefrostKeyImpl, FunctionKeyImpl, and NumericKeyImpl

class objects that maintains key state and handles key-press events. |

Object |

|

|

LCD |

Class

object that processes display data so that it is correct rendered on

the display screen. |

Object |

|

|

NumericKeyImpl |

Class

object that is used by the AutoDefrostKeyImpl class object.

NumericKeyImpl class object contains integer values of numeric keys

that have been pressed. |

Object |

|

|

Producer |

Role

stereotype of object association that shows the object is a producer of

data via the association arc. |

Association

Role |

|

Sequence Diagram

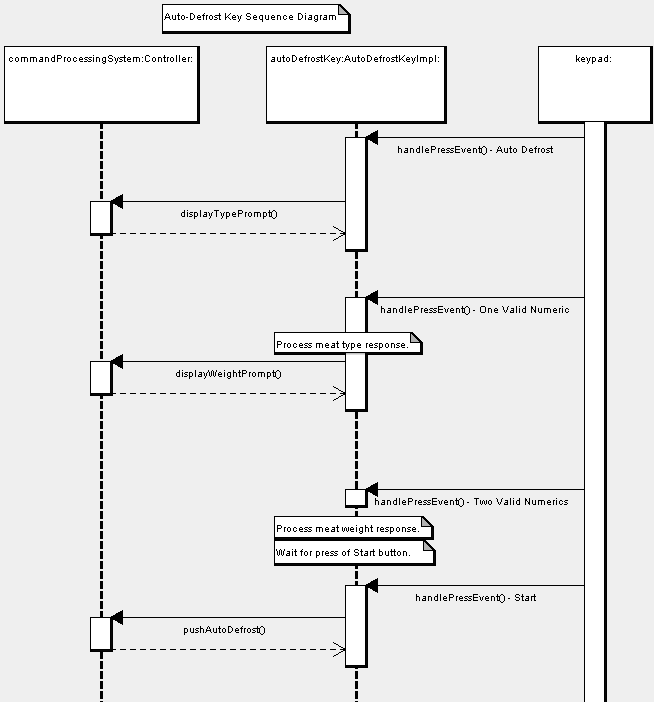

Sequence diagrams model the sequence of interactions between collaborating objects with the arrow of time pointing downwards. The first interaction or call would be at the top of the diagram just below the object squares. The second interaction would be the next call down and so on. Sequence diagrams are sometimes informally referred to as "lollipop diagrams" since the objects are shown as squares with long stems hanging down thus giving them the appearance of a lollipop. The reason for this odd type of symbol is that the interactions need to be drawn between objects in swimlanes so that the vertical spatiality of the diagram is easy to discern.The following sequence diagram models the interactions between the collaborating objects that fulfill the system's auto-defrost functionality for the microwave oven example.

Data Dictionary:

|

Term |

Description |

Type |

Requirements

Trace |

|

autoDefrostKey |

AutoDefrostKeyImpl

class object that contains and processes cooking duration and power

level data (via inheritance). Class object also contains and processes

type of meat and meat weight data. |

Object |

|

|

AutoDefrostKeyImpl |

Class

that contains and processes type of meat and meat weight data. |

Class |

|

|

commandProcessingSystem |

Controller

class object that manages controller data and system state and provides

services to other system objects. |

Object |

|

|

Controller |

Class

that manages controller data and system state and provides services to

other system objects. |

Class |

|

|

displayTypePrompt |

Method

of Controller class that displays meat type prompt on LCD. |

Method |

|

|

displayWeightPrompt |

Method

of Controller class that displays meat weight prompt on LCD. |

Method |

|

|

handlePressEvent |

Method

of AutoDefrostKeyImpl class that handles key-press events as they occur. |

Method |

|

|

pushAutoDefrost |

Method

of Controller class that displays meat weight prompt on LCD. |

Method |

Activity Diagram

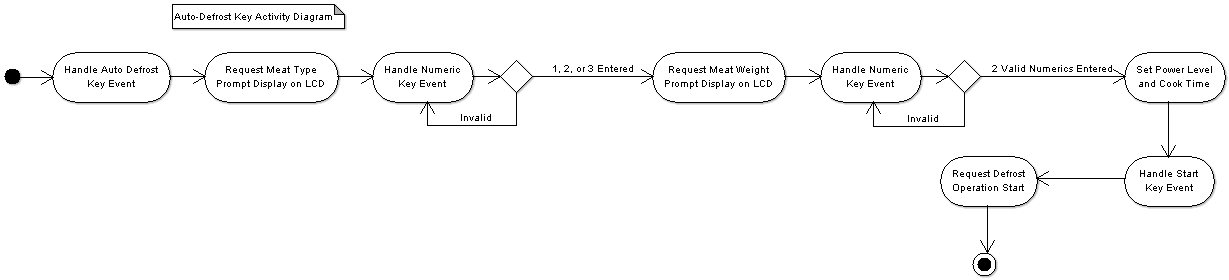

Activity diagrams are very similar to the previously discussed control flow diagrams. Activity diagrams show the flow of execution through the various activities that occur during a given operation. Activity diagrams are very semantically rich design artifacts and are therefore good tools for drilling down into the finest details of a detailed design.The following activity diagram models the flow of execution through the activities that are involved in processing an auto-defrost request from a user with regards to the microwave oven example.

Data Dictionary:

|

Term |

Description |

Type |

Requirements

Trace |

|

1,2, or

3 Entered |

Key-press

event representing user selected type of meat. |

Transition |

|

|

2 Valid

Numerics Entered |

Key-press

events representing user specified meat weight. |

Transition |

|

|

Handle

Auto Defrost Key Event |

Handling

activity of user key-press of auto-defrost key. |

Activity |

|

|

Handle

Numeric Key Event |

Handling

activity of user key-press of numeric key. |

Activity |

|

|

Handle

Start Key Event |

Handling

activity of user key-press of start key. |

Activity |

|

|

Invalid |

Invalid

keycode for key-press event. |

Transition |

|

|

Request

Meat Type Prompt Display on LCD |

Request

activity for display of meat type prompt by controller. |

Activity |

|

|

Request

Meat Weight Prompt Display on LCD |

Request

activity for display of meat weight prompt by controller. |

Activity |

|

|

Request

Defrost Operation Start |

Request

activity for start of generator in auto-defrost mode by controller. |

Activity |

|

|

Set

Power Level and Cook Time |

Data

processing activity for type of meat and weight of meat specified by

the user. |

Activity |

Pseudocode

Pseudocode can be anything from sentence fragments to a formally specified language. Pseudocode allows expression of operations in an easily readable from without being constrained by the demands of the compiler. Pseudocode also allows the creater to code at the level of detail currently known. Code that must be compiled might not lend itself to high levels of abstraction and low levels of detail and yet that level of detail might be exactly what the design artifact needs to capture and convey to the user of the artifact.Pseudocode for the auto-defrost key functionality of the microwave oven example follows.

BEGIN_AUTO-DEFROST

REQ_PROMPT_MEAT_TYPE

WAIT FOR NUMERIC

IF 1 THEN TYPE = BEEF, POWER_LEVEL = 5

ELSE IF 2 THEN TYPE = POULTRY, POWER_LEVEL = 3

ELSE IF 3 THEN TYPE = FISH, POWER_LEVEL = 1

ELSE ERROR_BEEP AND REPEAT WAIT FOR NUMERIC

END WAIT

REQ_PROMPT_MEAT_WEIGHT

WAIT FOR TWO NUMERICS //#.# LBS

IF TYPE = BEEF

COOK_TIME = 4_MIN * LBS

ELSE IF TYPE = POULTRY

COOK_TIME = 3.5_MIN * LBS

ELSE IF TYPE = FISH

COOK_TIME = 4.5_MIN * LBS

ELSE ERROR_EXIT

REQ_DEFROST_START(POWER_LEVEL, COOK_TIME)

END_AUTO-DEFROST

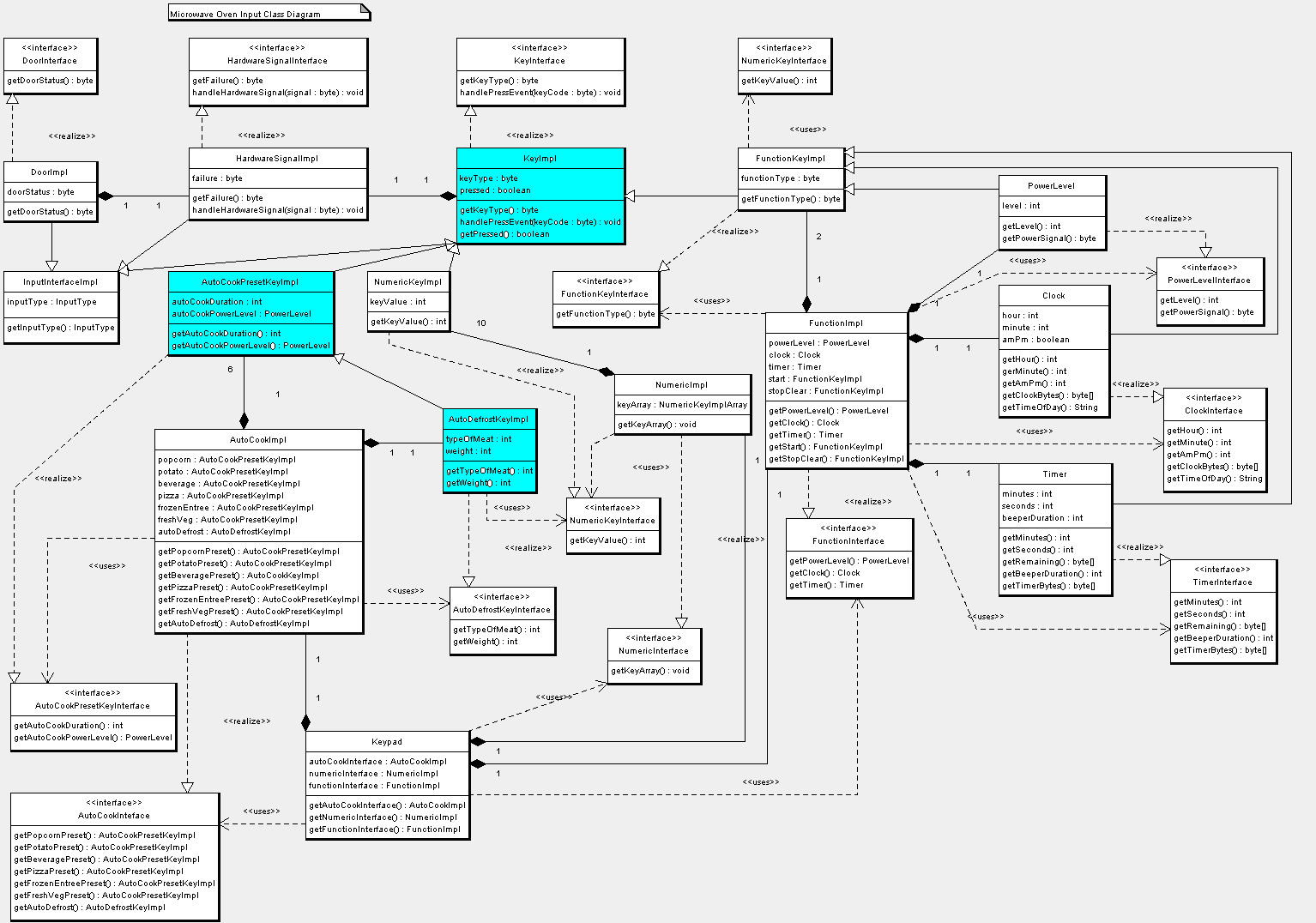

V-Model Diagram

As illustrated in the below V-Model diagram, at this point in the software development process, creation of unit test plans should begin. Unit tests must focus on the implementation details of the various software components of the system under development.